I-Natural Gypsum Powder Production Plant

I-Natural Gypsum Powder Production Plant

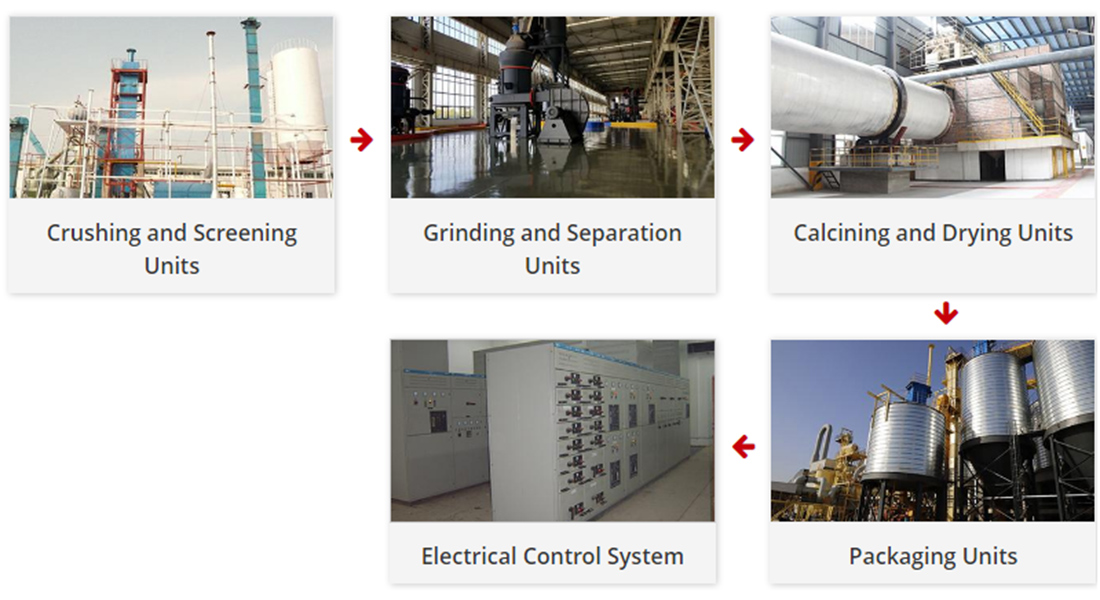

Inkqubo yeMveliso

Iinkqubo ezininzi zithathwa kwimveliso yesityalo.Okokuqala, intsimbi ekrwada yegypsum iyatyunyuzwa, ihanjiswe kwaye igcinwe kumgqomo wezinto ekrwada, emva koko iintsimbi zegypsum ezityunyuziweyo zigaywe zibe ngumgubo ngokucoleka okufunwa yi-raymond mill, kwaye umgubo wegypsum ugqithiselwa kwicandelo lokubala ngesixhobo sokutyisa iimitha ukuze ufumane. I-calcined, kwaye i-gypsum e-calcined iguqulwa yi-grinder kwaye ipholile ngesixhobo sokupholisa.Ekugqibeleni, i-gypsum egqityiweyo ihanjiswa ukuze igcinwe.

Lo mzimveliso unala macandelo/iiyunithi

IiParameters zokuSetyenziswa kwezinto

| Iitoni/Unyaka | Iitoni/Iyure | Ukusetyenziswa kwentsimbi ekrwada (iiToni/Unyaka) |

| 20000 | 2.78 | 24000 |

| 30000 | 4.12 | 36000 |

| 40000 | 5.56 | 48000 |

| 60000 | 8.24 | 72000 |

| 80000 | 11.11 | 96000 |

| 100000 | 13.88 | 120000 |

| 150000 | 20.83 | 180000 |

| 200000 | 27.78 | 240000 |

| 300000 | 41.66 | 360000 |

Inzuzo

1. I-feeder ye-mill ithatha i-frequency conveyor conveyor, isantya sayo sokuhamba sihambelana nombane wangoku wombane, kunye nomsebenzi wokutya okuzenzekelayo unokufumaneka ngolawulo oludibeneyo lwe-PLC.Xa kuthelekiswa ne-electromagnetic vibration feeder yemveli, i-feeder ineempawu zobomi obude benkonzo kunye nokutya okuzinzileyo.I-remover ye-iron esisigxina yemagnethi ibekwe kwindawo ephezulu yokuhambisa ibhanti, enokuthintela ngokufanelekileyo iimveliso zentsimbi ukuba zingangeni kwi-mill kwaye zibangele umonakalo kwi-mill;

I-2.I-powder eqokelelwe yi-bag filter ye-mill ihanjiswa ngokuthe ngqo kwisistim nge-screw conveyor ekhethekileyo yokunciphisa ubuninzi babasebenzi;

I-3.I-gypsum powder buffer bin ibekwe phakathi kokugaya kunye nokubala, enemisebenzi emibini.Okokuqala, inomsebenzi wokuzinzisa izinto eziphathekayo.I-powder ye-gypsum inokugcinwa okwethutyana apha ngaphambi kokuba ingene kwisithando somlilo esinamanzi.Xa ukukhutshwa kwangaphambili kungazinzi, ukondla okuzinzile kwesithando somlilo esinamanzi akuyi kuchaphazeleka.Okwesibini, inomsebenzi wokugcina.Ukuzinza kwe-calcination ye-gypsum powder kuxhomekeke kunikezelo oluzinzileyo lwezixhobo kunye nokunikezelwa kobushushu obuzinzile, kunye nokuphazamiseka kwinkqubo yokuvelisa kufuneka kugwenywe ngokusemandleni, kuba kukho iziphene ezisemgangathweni kwi-powder gypsum ngaphambi kokuqalisa nangemva kokuvala.Ukuba akukho silo esinjalo, izixhobo ezingaphambili ziya kuvalwa xa kukho ingxaki, kwaye umgangatho wokubala we-gypsum powder awuyi kuzinza xa unikezelo olungaphambili luzinzile;

4.Isixhobo sokuhambisa ukutya phambi kwesithando somlilo esinamanzi samkela isixhobo sokuhambisa iimitha.Ukutshintsha imowudi yokuhambisa i-frequency frequency, imisebenzi yokondla okuchanekileyo kunye nomthamo ocacileyo wemveliso inokuphunyezwa ngokusebenzisa ukuhanjiswa kwemitha;

5.Iziko lomandlalo oshushu oshushu lisetyenziswa kwisixhobo sokubala, kwaye senze uphuculo oluthile kwesi siseko:

a.Ukwandisa indawo yangaphakathi yesithando somlilo esinamanzi, ukwandisa ixesha lokuhlala kwi-gypsum powder kwindawo yangaphakathi, yenza ukuba i-calcination ibe yinto efanayo;

b.Inkqubo yokufakela ityhubhu yokutshintshiselana ngobushushu ngokuzimeleyo ephuhliswe yinkampani yethu inokuphepha ngokufanelekileyo ukuqhekeka kwegobolondo lebhedi yomlilo emanzi ebangelwa kukwandiswa kwe-thermal kunye nokucutha okubandayo;

c.Igumbi lothuli phezulu kwesithando somlilo esinamanzi sanda, kwaye isixhobo sokuqokelela uthuli lwangaphambili senzelwe kwindawo yokukhupha ukunciphisa ukukhutshwa kwe-gypsum powder kunye nokunyusa ukusebenza kakuhle kwemveliso yesithando somlilo esinamanzi;

d.Inkunkuma yokubuyisela ubushushu bobushushu bongezwa phakathi kweengcambu ezisezantsi zokuvuthela kunye nombhobho wokudibanisa wesithando somlilo.Umoya oqhelekileyo weqondo lokushisa ufudunyezwa ngumtshintshi wokushisa kuqala, uze wongezwe kwisithando somlilo esinamanzi, ukwenzela ukuba kwandiswe ukusebenza kakuhle kwe-thermal yesithando somlilo;

e.Isixhobo esikhethekileyo sokuhambisa umgubo simiselwe.Xa ingaphakathi lesithando somlilo esine-fluidized bed kunye ne-cooler kufuneka icocwe, umgubo uthuthwa kuqala kwi-bin yenkunkuma ngokusebenzisa izixhobo zokuhambisa ukufikelela kwindawo ecocekileyo yokusebenza.

6. I-cooler ekhethekileyo ye-gypsum powder isetyenzisiwe, kwaye i-gypsum powder cooler ibekwe emva ekupheleni kwesithando somlilo esinamanzi, esinokunciphisa ngokufanelekileyo ubushushu be-gypsum powder ngaphambi kokungena kwi-silo, kunqande ukubalwa kwesibini kwe-gypsum powder. i-silo, kwaye uqinisekise ngokufanelekileyo umgangatho we-gypsum powder;

7. Icandelo eligqityiweyo lokugcina imveliso linokwandiswa.Abathengi banokongeza umgqomo wenkunkuma we-gypsum kweli candelo.Xa i-powder engafanelekanga ibonakala ngexesha lokuqalisa kunye nokuvalwa, i-powder engafanelekanga ingathuthwa ngokuthe ngqo kwi-bin yenkunkuma ngokusebenzisa i-PLC yolawulo oluphakathi.I-powder ye-gypsum kwi-bin yenkunkuma ingathuthelwa kwinkqubo ngexabiso elincinci kwinkqubo yokuvelisa eqhelekileyo yebhodi ye-gypsum;

8. Izixhobo ezingundoqo Sisebenzisa abavelisi abadumileyo bamazwe ngamazwe njengamahlakani, i-PLC isebenzisa i-Siemens brand, kwaye i-burner isebenzisa i-brand ye-German Weso;

9. Inkampani yethu ineqela lokuqala loyilo loyilo, iqela lokuqala lokucubungula, ukufakwa kweklasi yokuqala kunye neqela lokulungisa, izixhobo zeklasi yokuqala.Sisiqinisekiso esiyimfuneko kubathengi ukuba bafumane iimveliso ezifanelekileyo nezizinzileyo.

Iimpawu zeSityalo sethu seNdalo seGypsum

1. Inkqubo yozinziso yesongezelelo sezinto eziphathekayo isetyenziselwe ukuphumeza ukongezwa okuzinzile kwebhoyila yokutshisa ibhedi, kunye nokuzinzisa ukongezwa kwezinto kunye nokufudumeza.Inkqubo yozinziso yesongezelelo seMaterial ibandakanya umgqomo wokuzinzisa kunye nesixhobo sokuhambisa (isixhobo sokulinganisa iimitha okanye isilinganisi sebhanti).

2. Inkqubo yokubala kusetyenziswa inkqubo yokubala umoya oshushu obilisa iziko ukwenza nokubalwa kwezinto zegypsum.

3. Isixhobo sokupholisa songezwe ukupholisa igypsum epholileyo phambi kokuba ingene esele, ukunqanda igypsum ekuwohlokeni okubangelwa bubushushu obugqithisileyo.

4. Inkqubo yokuguqula iSilo: imathiriyeli ngamaxesha ahlukeneyo ibonisa umgangatho owahlukileyo, ngoko ke iimveliso ezenziwe ngazo zibonisa umgangatho owahlukileyo.Inkqubo yokuguqula i-silo inokuxuba ngokulinganayo izinto ezintsha kunye nezidala, yenza iimveliso zabelane ngomgangatho ofanayo.Ngaphandle koko, inkqubo ithintela ukuwohloka kobushushu obugqithisileyo obubangelwa bubushushu obuveliswa kukuqokelelana komgubo.

5. Inkqubo yokususa uthuli isebenzisa umqokeleli wothuli wohlobo lwengxowa, ukuqinisekisa uthuli oluveliswa ngexesha lokumisa kwangaphambili, ukuhambisa, ukugaya, ukubala kunye neenkqubo zokuguga zihlanjululwe ngaphambi kokuba zikhuphe ngaphandle, ukuhlangabezana neemfuno ezisebenzayo zokusingqongileyo.

6. Inkqubo yolawulo olusasazwayo isetyenziswa, ukwenza ulawulo oluphakathi kwizixhobo ezisasazwayo.

Iiparamitha zeeMveliso zeGypsum

1.Ukulunga: ≥100 i-mesh;

I-2.Flexural Strength (ukuba nobudlelwane obuthe ngqo kwizinto eziluhlaza): ≥1.8Mpa;Amandla eAntipressure: ≥3.0Mpa;

3.Iziqulatho eziPhambili: I-Hemihydrate: ≥80% (Ukulungiswa);Gypsum <5% (Adjustable);I-Soluble Anhydrous <5% (Inokulungiswa).

4. Ixesha lokuqala lokuSeta: 3-8min (Inokulungiswa);Ixesha lokuSeta lokuGqibela: 6 ~ 15min (Inokulungiswa)

5. Ukungqinelana: 65% ~ 75% (Adjustable)