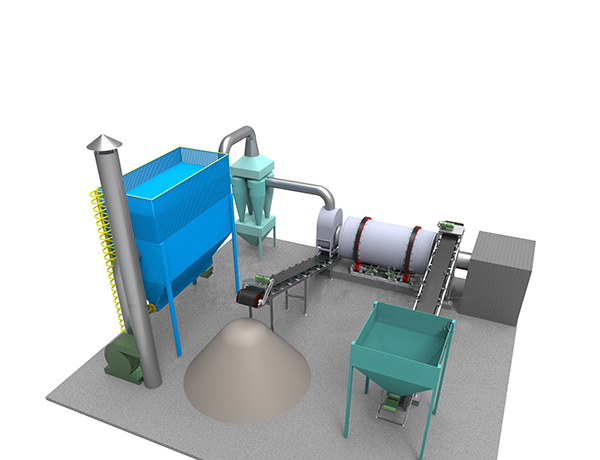

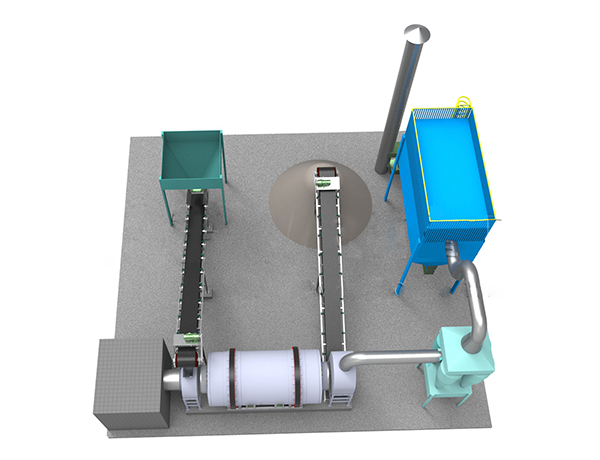

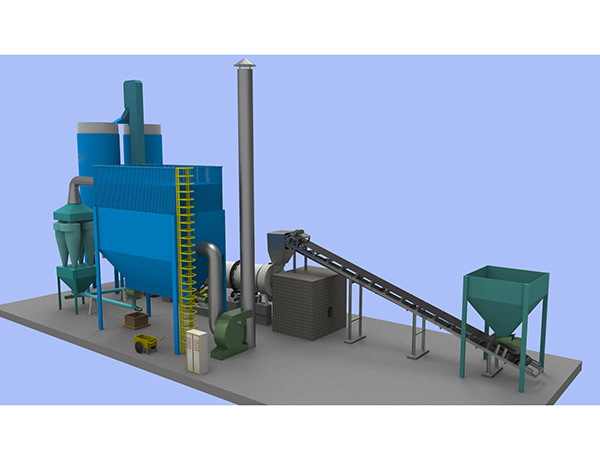

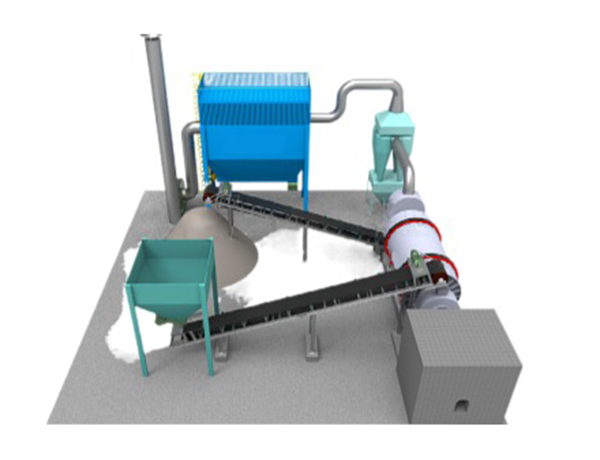

Inkqubo yokomisa izinto zeGranular

Inkqubo yokomisa izinto zeGranular

Izinto eziluncedo kwiNkqubo

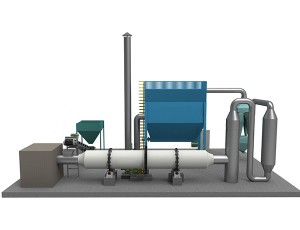

Ukusebenza okuphezulu kwe-thermal

Izinto zokugcinwa kobushushu ezinokumelana nobushushu obuphezulu, zidityaniswe nesici sokusetyenziswa kobushushu besomisi-cylinder ezintathu, umphumo wokonga amandla uyabonakala.

Utyalo-mali lwezixhobo eziphantsi

Ubushushu bezinto eziphathekayo ngu <50 ℃, enokungena ngokuthe ngqo kwindawo yokugcina impahla, kwaye isixhobo sokupholisa asifuni;Ubushushu begesi yomsila buphantsi, isixhobo sokususa uthuli sinobomi obude benkonzo.

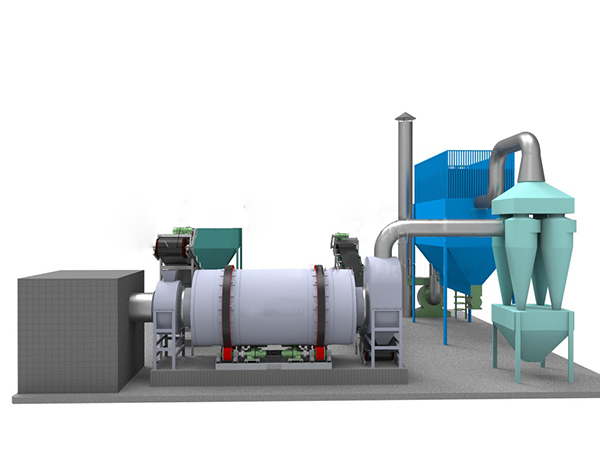

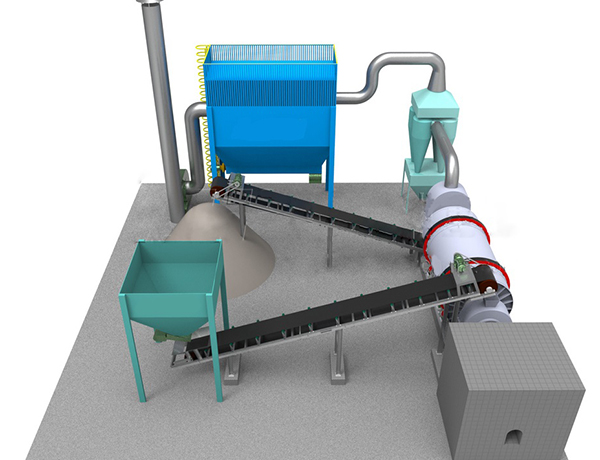

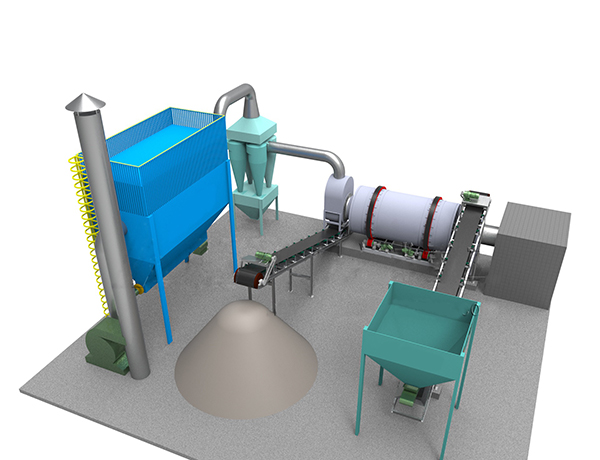

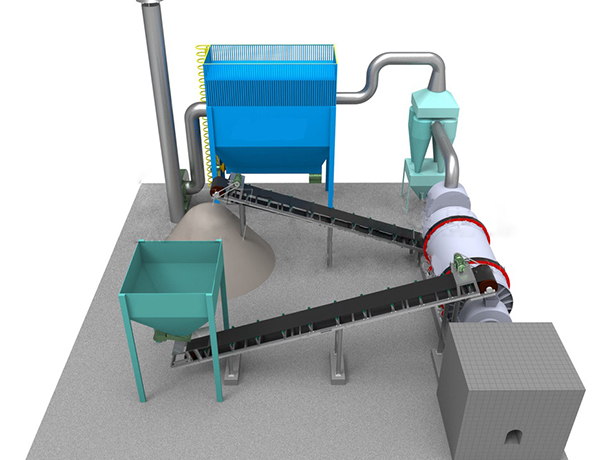

Indawo encinci yomhlaba, kulula ukuyifaka

Indawo yayo ehlanganisiweyo i-50% ngaphantsi kweyomileyo ye-cylinder eyodwa, utyalo-mali lokwakha luncitshiswe ngama-50% kwaye ukusetyenziswa kombane kuncitshiswe ngama-60%, ukucwangciswa kwenkqubo yokomisa kuhambelana nokuhamba kwenkqubo elula.

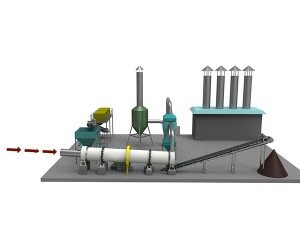

Umgaqo wokuSebenza

Izinto eziphathekayo zityiswa kwi-onti nangona ekupheleni kwe-kiln (icala eliphezulu le-cylinder).Ngenxa yokuba i-cylinder ithambekele kwaye ijikeleza ngokucothayo, izinto eziphathekayo zihamba kunye nesangqa kunye ne-axial direction (ukusuka kwicala eliphezulu ukuya kwicala elisezantsi).Emva kokutshintsha umzimba kunye neekhemikhali, izinto zingena kumatshini wokupholisa ngesigqubuthelo sentloko se-oven emva kokugqiba ukubala.I-fuel ifakwe kwintloko ye-oven ngentloko ye-oven, kwaye i-exhaust gas iya kuphuma ekupheleni kwe-oven emva kokutshintsha ubushushu ngezinto.

IiParameters zobuGcisa ze-Three Cylinder Dryer

| Umzekelo | Idatha yesilinda | Umthamo (t/h) | Isantya se-cylinder rotary (r/min) | Amandla (kW) | ||||

| Idayamitha yesilinda yangaphandle (m) | Ubude besilinda sangaphandle (m) | Umthamo wesilinda (m3) | Umlambo isanti | Bhabha uthuthu | I-Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2×4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3×2 |

| VS2×5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4×2 |

| VS2×6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5×2 |

| VS2.2×4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5×2 |

| VS2.5×6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5×4 |

| VS2.7×7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5×4 |

| VS2.8×6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5×4 |

| VS3×6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5×4 |

| VS3×7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5×4 |

| VS3.2×7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11×4 |

| VS3.2×8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11×4 |

| VS3.6×8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15×4 |

| VS3.8×9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15×4 |

| VS4×10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5×4 |

| VS4.2×8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5×4 |

Iimveliso ezomileyo